To build a prototype the goal is to de-risk and validate our assumtions first, and to fail quickly. So every prototype built will be different, and steps to build them will not follow the same order.

Hardware

Requirements

To build good prototype it is important to iterate quickly, so once the idea is sketched out, the requirements can be specified.

Choosing components

Finding parts that match the requirements and getting off the shelf parts is critical to building a prototype, as custom parts are expensive and time consuming to design, to make and to test.

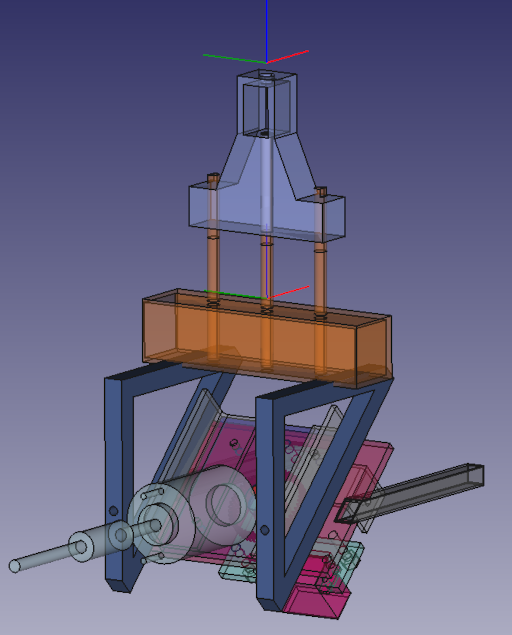

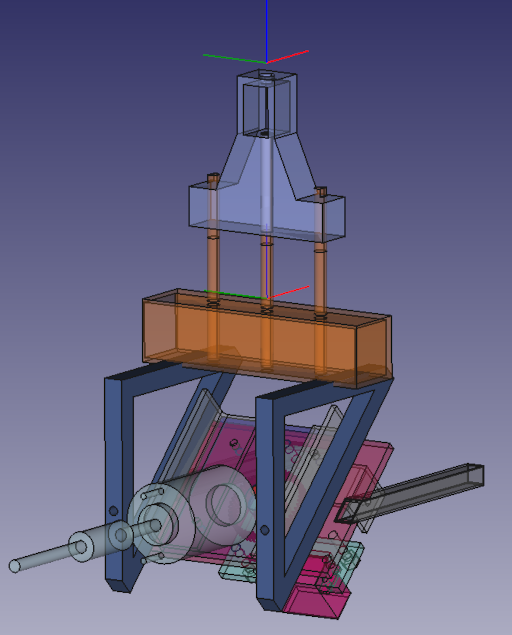

Manufacturing

Depending on the requirements, the manufacturing methods will dictate the way a part is built, 3D printed, milled, turned, laser or plasma cut, bent,

etc.

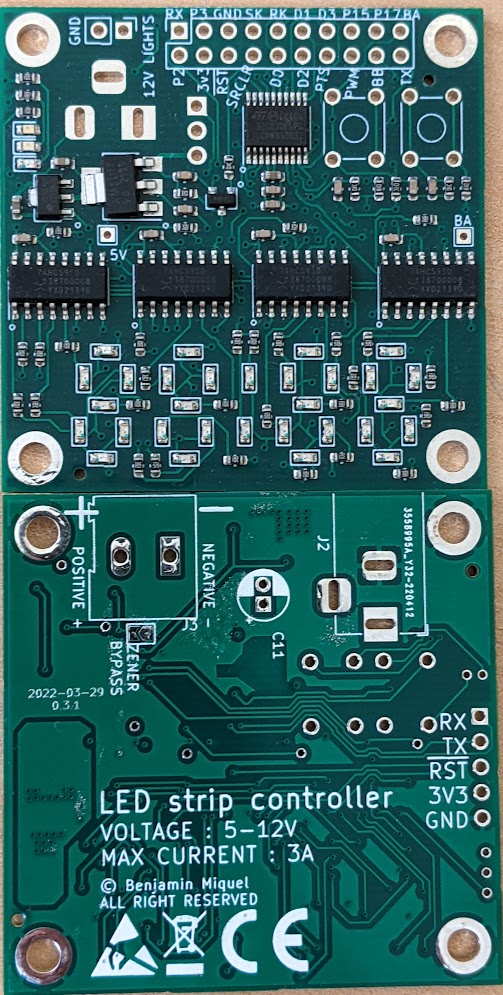

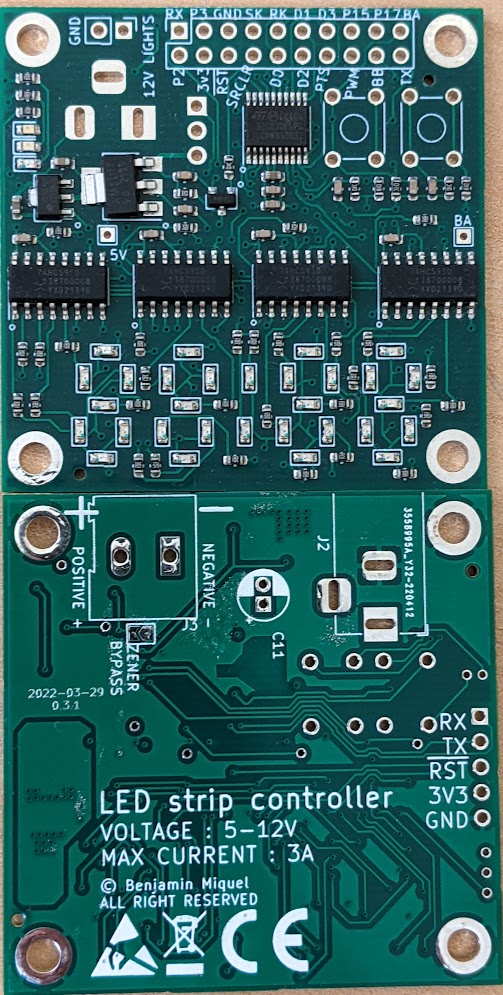

Electronics

Power

Power is the most important part of designing good electronics, it may not always be the most complicated part of a system but it dictates all the critical characterisitcs of the board such as the thermals, the current paths, the connectors, the clearances, the electro-magnetic radiation.

Sensors

With so many suppliers and technologies out there, it is complicated to choose the right sensors on the first try, so making protoypes means being able to change sensor, to test new ways of gathering data, and being able to debug sensors.

Manufacturing

Desiging PCBs, assembling them, building harness, creating diagrams, managing supply chains, ensuring the quality of the components, trouble shooting issues, and reworking PCBs are all parts of manufacturing electronics.

Software

Controller

Controlling what the hardware does is the whole point of automating a system. Creating state machines, ensuring proper sequencing of processes, calibrating the sensors, developping unit and integration tests.

Drivers

Writing drivers for every sensor and sub-system, and managing the different communication protocols and buses such as SPI, I2C, CAN, Ethernet, UART, DMA. Testing the different features and ensuring that the ICs work properly, troubleshooting using logic analysers.

Software

Software should be the core part of all companies today, data analysis, statistics, pipelines, scripts, web applications, and hacking have been big part of my professional carreer, this is what tie everything together and ensure that complex system work together.